Is There Really a Future for Polyester Recycling?

Europe and the industry are betting on it. A review of SystemIQ's textile recycling breakthrough report.

"Recycling of polyester textile waste in Europe will not reach a breakthrough in scale without significant policy action."

That's how SystemIQ opens their latest report, and honestly, it sets the tone for everything that follows.

The report explores the policy pathways needed to scale polyester textile recycling in Europe, developed in collaboration with Textile Exchange, Fashion for Good, Circle Economy, and other key industry stakeholders.

El Problem

Let me start with the numbers that should make us all uncomfortable:

Over 125 million tonnes of material consumed by global textiles industry

Less than 1% of textiles made from recycled textile waste

87% of textile waste is landfilled or incinerated, or exported to regions that can't handle it

Textiles drive ~14% of global micro- and macro-plastic pollution

Even natural fibers contribute to microfiber pollution due to dyes, coatings, and finishes

We are at a tipping point towards potential complete system failure. And I don’t mean only ecologically.

Export markets that used to absorb textile waste are collapsing. For instance, in Ghana's Kantamanto Market (one of the world's largest second-hand clothing hubs) between 5-40% of the 15 million garments arriving each week are deemed unsellable. And where do those go? To open landfills and informal waste streams (such as beaches).

And it isn't only in Ghana. Just last week, WRAP released a report warning about the UK textile collection sector potentially collapsing. They noted that UK textile collectors already spend £88 million annually dealing with unwanted clothing. If this sector fails, local authorities could face an additional £64 million in disposal costs annually. That's on top of the £73 million they already spend on textile management.

Translation: managing our textile waste is becoming expensive as hell, and someone has to pay for it.

But before diving into Europe's proposed solution, we need to understand the recycling landscape. There are two main approaches to textile recycling, each with dramatically different capabilities and costs.

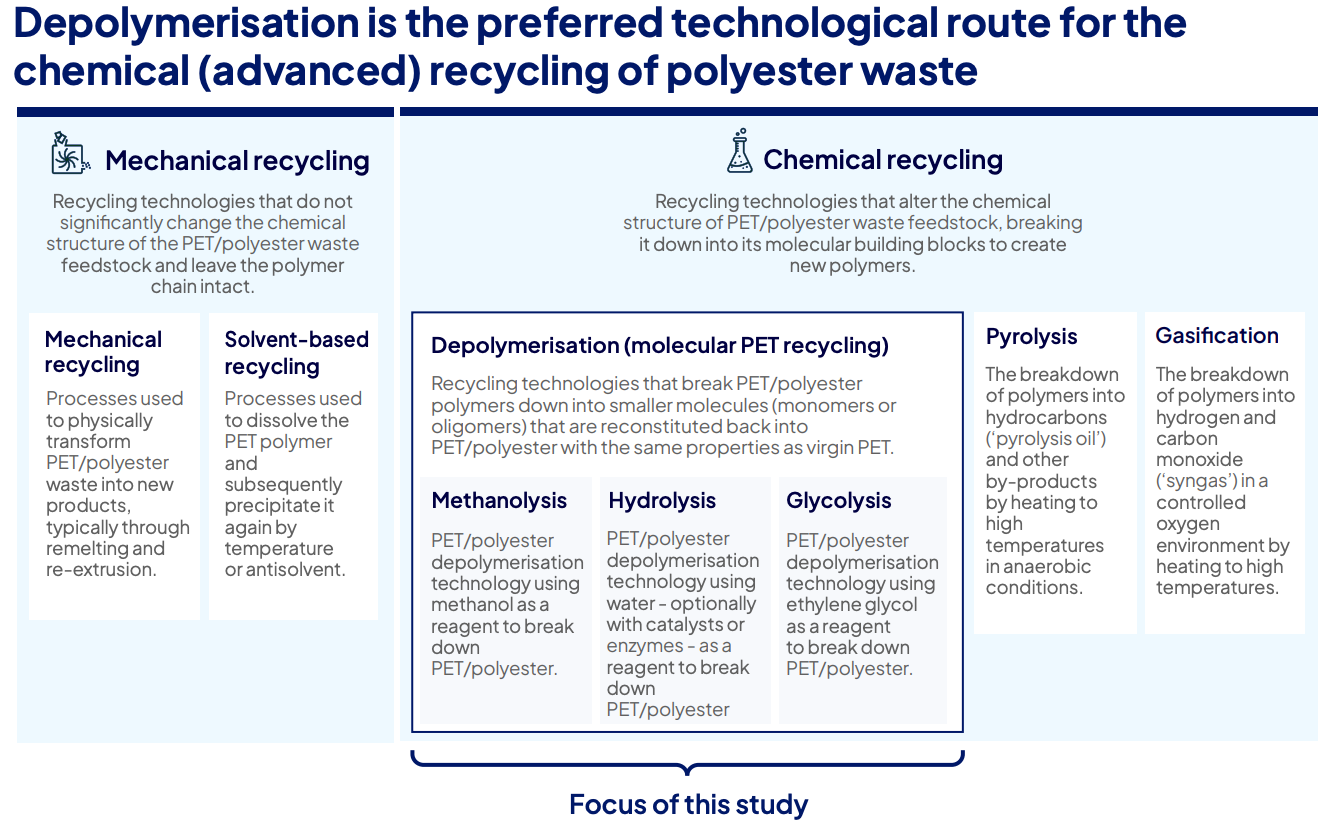

El Side Note: Chemical vs. Mechanical Recycling

Not all recycling is created equal. While the fashion industry loves to throw around the word "recycled," the reality is that most of what we call recycling today is just downcycling, turning your old t-shirt into insulation material. The technical differences between mechanical and chemical recycling determine whether we're actually solving the problem or just delaying it.

Mechanical Recycling transforms polyester waste without altering its chemical structure. It includes traditional mechanical methods like remelting and re-extrusion, as well as solvent-based processes that dissolve and re-precipitate the polymer using temperature changes or antisolvents. These methods are widely used but limited to uncontaminated, single-fiber textiles and often result in lower-quality outputs.

Pros:

Low energy consumption and fewer resources required

Simple and low-cost process with established infrastructure

Can maintain some fiber properties for certain applications

Cons:

Degrades quality with each cycle (remember our plastic recycling conversation?)

Gets contaminated by dyes, finishes, spandex, titanium dioxide

Can't handle fiber blends (30% of post-consumer textile waste)

Shortens fiber length and decreases quality to lower-value products

Inconsistent color output and dye uptake leading to high re-dyeing rates

Chemical Recycling, by contrast, breaks polyester down to its molecular building blocks, enabling the production of virgin-quality material. This report focuses on depolymerization methods (methanolysis, hydrolysis, and glycolysis) which use different reagents to break down PET and are capable of handling blends and contaminated inputs. Other approaches like pyrolysis and gasification also alter the polymer at a chemical level but fall outside the study’s scope.

Pros:

~55% lower emissions than virgin polyester production

Can handle contaminated and blended textiles

Maintains fiber quality and can produce virgin-equivalent outputs

Can process mixed fiber textiles with various additives

Rapid processing possible (15 minutes with microwave-assisted methods)

Cons:

Costs 2.6 times more than virgin polyester from Asia

Requires massive infrastructure investment

Still energy-intensive process requiring high temperatures

Often requires solvents with high environmental impact

Limited commercial scale deployment currently

Given these trade-offs, Europe is betting heavily on chemical recycling, specifically depolymerization, as the breakthrough technology. But making it economically viable requires a comprehensive policy response.

El Report

So how is Europe responding to this crisis? Enter EU's Extended Producer Responsibility (EPR). The idea? Make fashion brands and textile producers pay fees to fund textile waste collection and treatment costs.

Note: All SME fashion brands selling textile products in EU markets, regardless of company size or revenue, must comply with Extended Producer Responsibility regulations, creating significant compliance burdens for smaller companies that often lack the resources to manage complex data collection, reporting requirements, and fees across multiple EU member states.

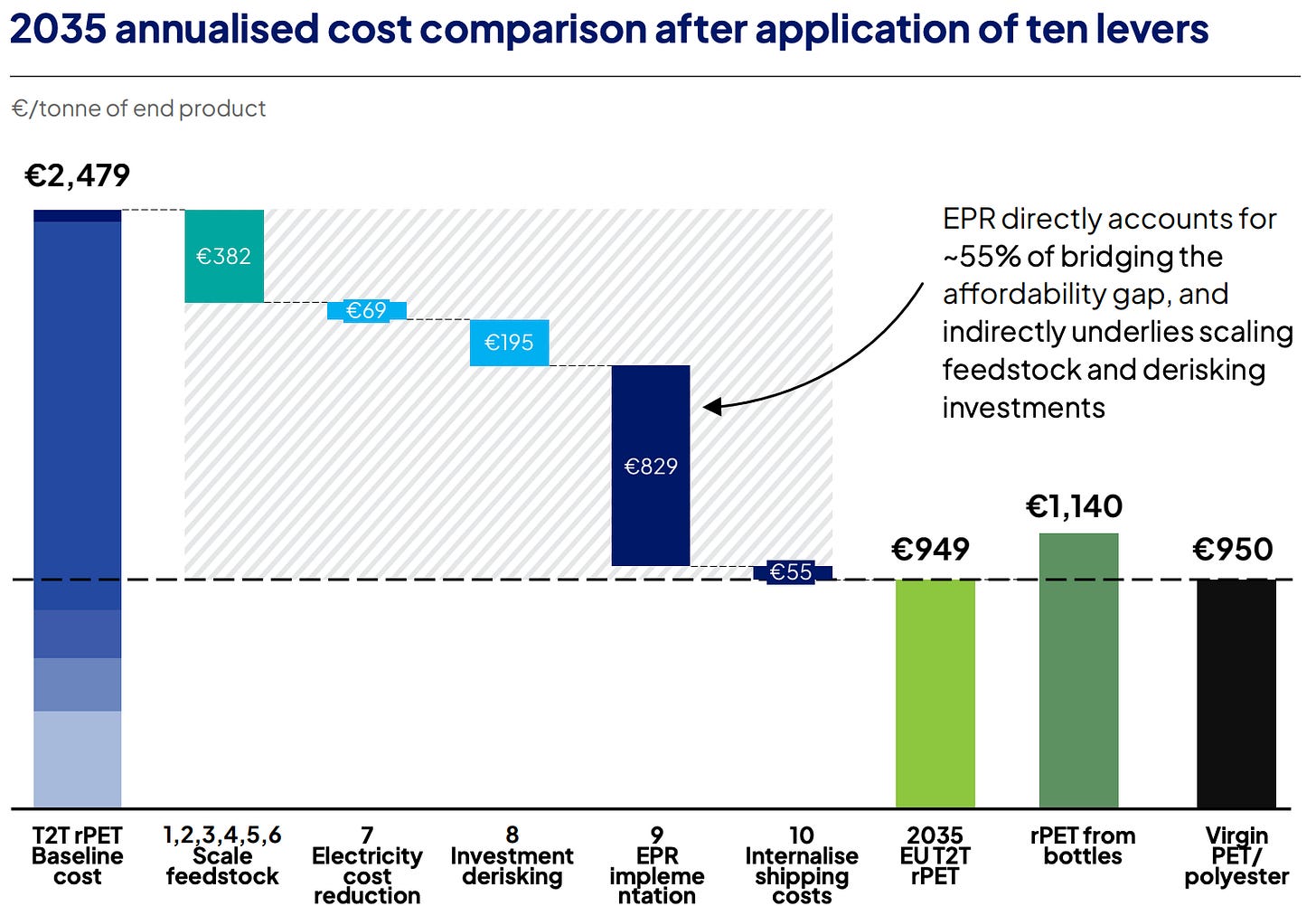

SystemIQ's proposed textile EPR:

€250/tonne by 2028, rising to €330/tonne by 2035

Should cover ~55% of the cost gap between recycled and virgin polyester

Combined with a €55/tonne green premium = €385/tonne total cost uplift

Compare to current proposals, such as those in The Netherlands, which land at ~€120–220/tonne

Well, Europe is betting big on recycled plastic. With aggressive regulatory momentum, the Clean Industrial Deal, and national investments like France 2030, it seems like that's the bet.

Recent announcements such as Circ's $500M Poly-Cotton Plant in France (world's first large-scale facility for recycling poly-cotton blends, backed by Macron and EU funds) and Reju's Regeneration Hub One (Netherlands) make me feel like the strategy in this report is indeed possible. And, according to the report, 25% of the cost gap could be closed through economies of scale and learning effects. Europe is positioning itself as the global hub for textile recycling innovation.

Other noteworthy key takeaways:

European depolymerisation output could grow nearly tenfold, from around 30,000 to 300,000 tonnes annually by 2035

This would represent about 15% of Europe's projected polyester demand in that year

Today, recycled polyester costs ~2.6 times more than virgin polyester from Asia

A broader system change across PET packaging and polyester textiles could generate €5.5 billion in annual value and create 28,000 net new jobs by 2040

So, what does the report say we do? 10 levers to make polyester recycling viable:

The study identifies ten levers across four essential areas of intervention:

A) Improve access to feedstock:

Implement design for recycling. Using limited materials, avoiding hard-to-recycle fiber blends, selecting dyes that don't hinder recycling, avoiding glued components. Experts suggest ~1/3 of textile products could be redesigned without compromising functionality

Establish widespread separate collection. Through EPR systems and nationwide bring-points, targeting 43% collection rates by 2030 and 50% by 2035

Set standards for sorting for recycling. Standardizing feedstock specifications to reduce fragmentation and investment uncertainty

Establish clarity on trade. Setting precise legal boundaries for "end of waste" and distinguishing reusables from waste for export

B) Strengthen offtake demand:

Create demand-side policy incentives. Including recycled content targets at raw material level, differentiated by feedstock source

Ensure brand & supply chain commitments. Long-term collaboration and demand planning between brands and strategic supply chain partners

C) Reduce production costs:

Reduce EU energy prices. 20% reduction in industrial electricity prices could lower depolymerisation costs by ~3%

Derisk investments. Lowering weighted average cost of capital from 17.5% to 12% could reduce costs by additional ~8%

D) Level the remaining cost gap:

Fully cover net costs with EPR. €250/tonne by 2028 rising to €330/tonne by 2035 to finance collection, sorting, and recycling

Internalise shipping costs. Green premium of ~€55/tonne to cover shipping costs to international production value chains

All these levers together gets us to price parity. Hooray!

Mi Take

But here's what gets me: if we haven't figured out recycling for packaging which we've been trying since the 80s/90s in various European countries and the US why do we think polyester textile recycling will be a magic solution?

And even with this EPR, we need some of it to go to the global south to support the management of textile waste from the global north.

The report acknowledges that even with a 10× scale-up, we'd reach about 300,000 tonnes of output per year by 2035. That's only ~15% of expected polyester textile consumption in Europe by 2035.

Let me repeat that: a massive, 10× increase in recycling capacity would handle 15% of just polyester consumption. We're not even talking about cotton, wool, or other fibers.

I do think recycling is necessary in a circular economy of course it is. But are we avoiding the hardest conversation: reduced consumption?

The report acknowledges this briefly: "Combining chemical recycling, PET/polyester reduction, reuse, and mechanical recycling across textiles and packaging could create 28,000 net new jobs by 2040." Notice how reduction is just one item in that list, not the primary focus.

Does textile recycling give us the same false sense of security as plastic packaging recycling? Are we creating a more sophisticated way to maintain our overconsumption habits?

This is a great report from a strategic perspective. I agree with Willem Swager from Patagonia that "This report offers a clear and actionable roadmap to unlock recycling of polyester textile waste at scale." It shows how Europe could dominate the textile recycling space through smart policy and massive investment. The technology is promising, and the industrial strategy is sound.

But is it truly a path to a more sustainable future? I can't shake the feeling that we're investing in managing the symptoms of overconsumption rather than addressing the root cause.

The conversation we still aren't having? How to design a system that needs less recycling because it produces less waste in the first place. I think the most impactful thing brands can do is commit to using synthetics only for performance-based apparel. Not every basic t-shirt needs to be made from plastic, recycled or otherwise.

🫒 What this means for SME brands

So, what does this mean for you as SME brands?

There's potential for reaching cost parity between virgin and recycled polyester by 2035, so if you use polyester, prepare for this transition.

Use upcoming EPR regulations as a way to get brand leadership support for recycled content, durable products, recyclable products, adopting practices such as repair, resale, rental, and upcycling.

Work with your design team to design for recyclability, meaning avoiding blends where possible, and minimizing chemical finishes.

Commit to next-gen materials that are truly biodegradable for non-performance applications (or recycled polyester if that is your thing).

If you feel ambitious: Internalize shipping costs and derisk investments by partnering with recycling initiatives like Fiber Club.

Sources

SystemIQ, "The Textile Recycling Breakthrough" (2025) - https://www.systemiq.earth/reports/the-textile-recycling-breakthrough/

WRAP, "Charities, local authorities and the public to bear cost of UK's used textiles crisis" (2025) - https://www.wrap.ngo/media-centre/press-releases/charities-local-authorities-and-public-bear-cost-uks-used-textiles

Sourcingjournal, "Is Europe Ready for a Textile-to-Textile Recycling 'Tipping Point'?" (2025) - https://sourcingjournal.com/sustainability/sustainability-materials/europe-systemiq-polyester-textile-recycling-tipping-point-1234749274/

H&M Foundation, "How textile-to-textile recycling went from vision to future standard" (2025) - https://hmfoundation.com/2025/04/03/how-textile-to-textile-recycling-went-from-vision-to-future-standard/

Ecotextile News, "Report urges policy action on polyester recycling" (2025) - https://www.ecotextile.com/2025052156936/news/materials-production-news/report-urges-policy-action-on-polyester-recycling/

COSH!, "How sustainable is recycled polyester? The pros and cons" (2024) - https://cosh.eco/en/articles/how-sustainable-is-recycled-polyester

Science Advances, "Chemical recycling of mixed textile waste" (2024) - https://www.science.org/doi/10.1126/sciadv.ado6827

Weavabel, "What are the Pros and Cons of Recycled Polyester?" (2024) - https://www.weavabel.com/blog/what-are-the-pros-and-cons-of-recycled-polyester

Green Chemistry, "Chemical recycling of polyester textile wastes: shifting towards sustainability" (2024) - https://pubs.rsc.org/en/content/articlehtml/2024/gc/d4gc00911h